Rob Bröker

Eigenaar Watson Excellent Operations en partner van Watson & Associates

+31 (0) 6 42 82 73 87 weo@watsonassociates.nl

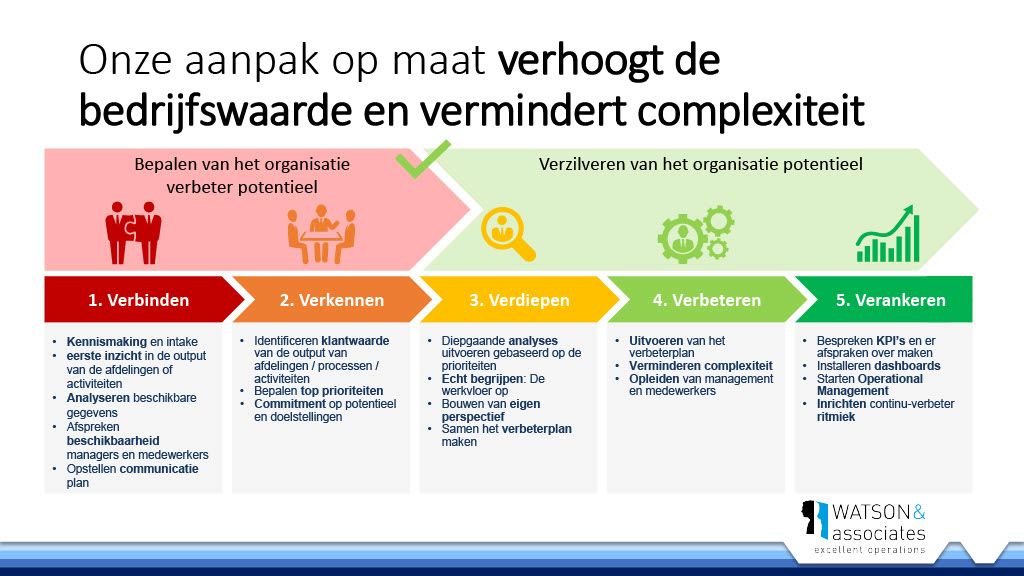

We verhogen de kwaliteit en de voorspelbaarheid en zorgen er samen met u voor dat uw organisatie voldoet aan alle eisen van klanten en wetgeving. We focussen ons op het verhogen van de kwaliteit omdat we weten dat dan de kosten vanzelf structureel omlaag gaan en de efficiency zal verbeteren.

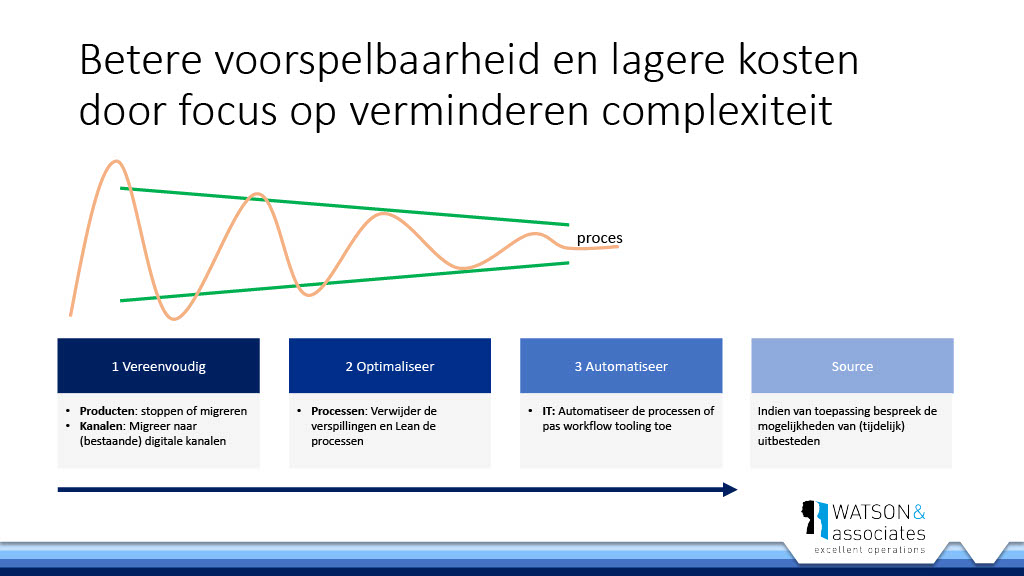

Het moet weer overzichtelijk worden. Gelijke dingen behandel je gelijk, ongelijke dingen behandel je ongelijk. Hoe divers zijn onze producten eigenlijk, maken we gebruik van de juiste kanalen? Zit er niet teveel ruis in onze werkwijze en levert onze werkwijze voorspelbare resultaten op? Samen gaan we hiermee aan de slag en bereiden de organisatie voor op verdere automatisering.

De aanpak is erop gericht dat uw organisatie zelf in staat wordt gesteld door te gaan met verbeteren. Zónder blijvende hulp van buitenaf. We geven vooraf aan wat we gaan doen en wat u kunt verwachten.

Wil je meer weten of even sparren of onze propositie jou ook zou kunnen helpen?

Bel met Rob, Vincent, Roald of Herman of stuur een mail naar WEO@Watsonassociates.nl

Je mag natuurlijk ook langs komen op ons kantoor:

Watson Excellent Operations

De Mulderij 8

3831 NV Leusden

Nederland

Eigenaar Watson Excellent Operations en partner van Watson & Associates

+31 (0) 6 42 82 73 87 weo@watsonassociates.nlAssociate Watson & Associates

+31 (0) 6 24 44 33 50 herman.elferink@watsonassociates.nl